EV Breakthrough: Stator and Rotor Development Boosts Motor Efficiency

An important development is about to occur in the electric vehicle (EV) sector. Recent advancements in stator and rotor technology are set to revolutionize electric motor efficiency, leading to longer-range and faster-charging EVs. As manufacturers strive for greener and more efficient vehicles, these developments could mark a key turning point in EV adoption.

Enhanced Motor Performance Through Stator and Rotor Design

One of the most significant areas of innovation in the EV sector lies in the design and materials used for the stator and rotor. The motor’s performance is mostly determined by its stator, which is its stationary part, and its rotor, which revolves inside the stator. Traditionally, stators and rotors were made using standard electrical steel, but with new breakthroughs, manufacturers are now utilizing high-performance materials, including advanced steel laminations.

These innovations in stator and rotor lamination, particularly the integration of silicon steel alloys, contribute to higher energy conversion efficiency. This improvement reduces energy loss during the conversion from electrical to mechanical power, thus enhancing overall motor performance. The design improvements, such as the use of specialized coatings, further reduce friction and heat generation, which can be detrimental to motor longevity.

The development of rotor stacks and stator stacks plays a critical role in this progress. By optimizing the way these stacks are manufactured and assembled, engineers can create motors with better torque characteristics and less electrical resistance. This means that for the same energy input, an EV can achieve higher power output, making the motor more efficient in converting energy to drive the vehicle.

Key Developments in Manufacturing and Materials

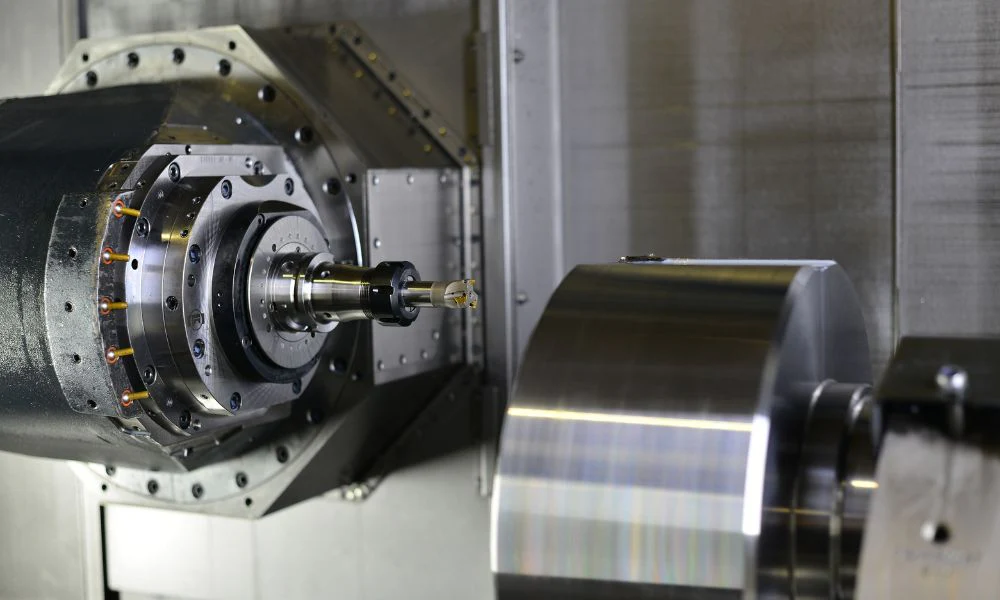

Another important advancement is in the manufacturing process. Traditional methods of laminating stator and rotor components have been improved, using precision cutting techniques like laser cutting and high-speed stamping. These methods reduce material waste and ensure that each lamination is perfectly aligned, which is crucial for maximizing motor efficiency. In addition, advancements in mold design have led to more accurate production of rotor and stator stacks, contributing to better overall motor performance.

Moreover, innovations in cooling technologies have helped address one of the major challenges facing EV motors: heat management. Advanced cooling systems are being integrated into stator and rotor assemblies to maintain optimal temperature levels during operation. By keeping temperatures in check, manufacturers can prevent overheating, which is a common issue that reduces efficiency and shortens motor lifespan.

Additionally, rotor and stator developments are being complemented by the introduction of stronger, lighter materials. For instance, carbon fiber and aluminum alloys are replacing traditional materials in some motor designs, allowing manufacturers to create lighter motors that still deliver the same power output. This is particularly important for EVs, where weight reduction directly translates into better performance and increased driving range.

The Future of Electric Vehicle Motors

As the EV market continues to grow, these improvements in stator and rotor technology are expected to lead to more affordable, efficient, and powerful electric motors. The integration of these advanced components into EV powertrains will not only improve performance but also reduce overall manufacturing costs, making electric vehicles more accessible to a wider range of consumers.

Further research is already underway to push the boundaries of stator and rotor stack development. The goal is to continue improving motor efficiency, which will be critical in achieving the long-term vision of electric vehicles as the dominant mode of transportation.EV motors appear to have a bright future because of developments in stator and rotor technology, which will enable them to achieve higher energy densities and quicker charging periods.

Conclusion

The evolution of stator and rotor designs is undoubtedly one of the key enablers in the development of next-generation electric vehicles. As manufacturers refine these components, the motors driving the EV revolution will become increasingly efficient, powerful, and affordable. In addition to being a significant milestone for the automotive sector, this innovative technology represents a global advancement in the shift to cleaner, greener transportation.