What are the signs of wear and tear in a rotary airlock valve?

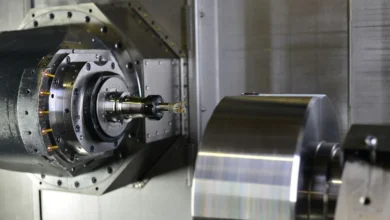

Rotary airlock valves play a crucial role in numerous industrial processes, serving as essential mechanical devices that control material flow between different pressure systems. These robust mechanisms are fundamental in managing bulk materials across various industries, including manufacturing, food processing, and chemical production.

Functional characteristics

The primary purpose of a rotary airlock valve is to create a seal between two different pressure environments while allowing consistent material transfer. Its unique design enables smooth material handling, preventing air leakage and maintaining system integrity. Precise engineering ensures these valves can withstand challenging operational conditions.

Early warning signs of potential issues

Detecting wear and tear early can prevent significant equipment failure and production interruptions. Operators must remain vigilant about several critical indicators that suggest potential valve deterioration:

- Irregular material flow patterns

- Unexpected pressure fluctuations

- Unusual noise during operation

- Visible physical damage

- Reduced sealing effectiveness

Mechanical wear indicators

Mechanical components experience continuous stress during operational cycles. rotary valves by Carolina Conveying demonstrate specific wear patterns that require careful monitoring. Rotor blade erosion, shaft misalignment, and bearing degradation represent primary mechanical wear concerns.

Visual inspection techniques

Regular visual assessments help identify potential problems before they escalate. Key areas to examine include:

- Rotor blade surface condition

- Seal integrity

- Housing alignment

- Shaft rotation smoothness

- Clearance between rotor and housing

Advanced diagnostic approaches

Sophisticated diagnostic methods complement traditional visual inspections. Thermal imaging, vibration analysis, and acoustic monitoring provide deeper insights into valve performance. These techniques enable proactive maintenance strategies, minimizing unexpected downtime.

Performance degradation signals

Subtle changes in operational characteristics often indicate underlying wear and tear. Rotary air lock valve performance may deteriorate through:

- Increased material leakage

- Reduced material transfer efficiency

- Inconsistent rotational movement

- Higher energy consumption

- Decreased overall system reliability

Critical component assessment

Careful examination of specific components reveals potential wear mechanisms:

- Rotor blade edge wear

- Seal material compression

- Shaft bearing condition

- Internal surface abrasion

- Clearance tolerance variations

Root cause analysis of wear mechanisms

The wear progression helps develop effective maintenance strategies. Primary factors contributing to valve deterioration include:

- Abrasive material characteristics

- Operational temperature variations

- Pressure differential stress

- Frequency of operational cycles

- Material particle size and composition

Mitigation strategies

Proactive maintenance approaches can significantly extend valve operational life:

- Regular lubrication

- Precise alignment checks

- Periodic clearance measurements

- Comprehensive cleaning protocols

- Strategic replacement of wear-prone components

Impact of wear on system performance

Continuous wear progressively compromises valve functionality. Potential consequences include:

- Reduced material transfer efficiency

- Increased energy consumption

- Higher maintenance requirements

- Potential production interruptions

- Compromised system reliability

Preventive maintenance framework

Developing a robust maintenance strategy involves:

- Establishing baseline performance metrics

- Creating systematic inspection schedules

- Implementing predictive monitoring techniques

- Training personnel in diagnostic procedures

- Maintaining comprehensive maintenance records

Effective rotary airlock valve management requires consistent monitoring, strategic maintenance, and timely intervention. Industry can improve equipment performance and minimize operational disruptions by implementing comprehensive diagnostic approaches and implementing wear mechanisms.